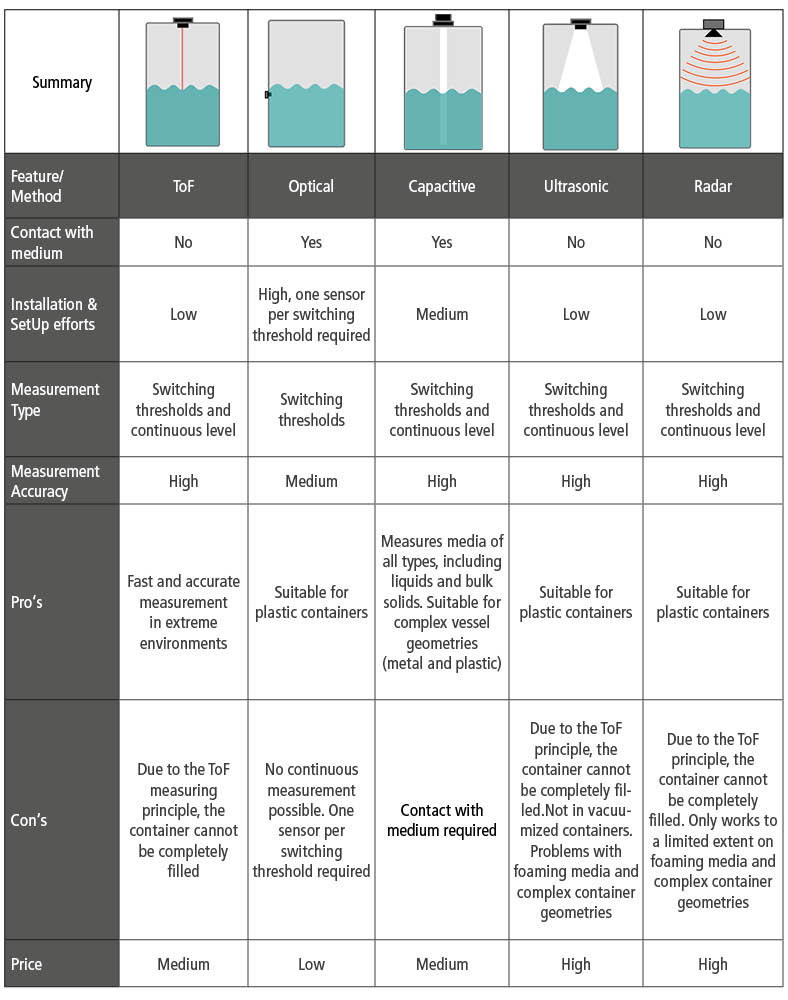

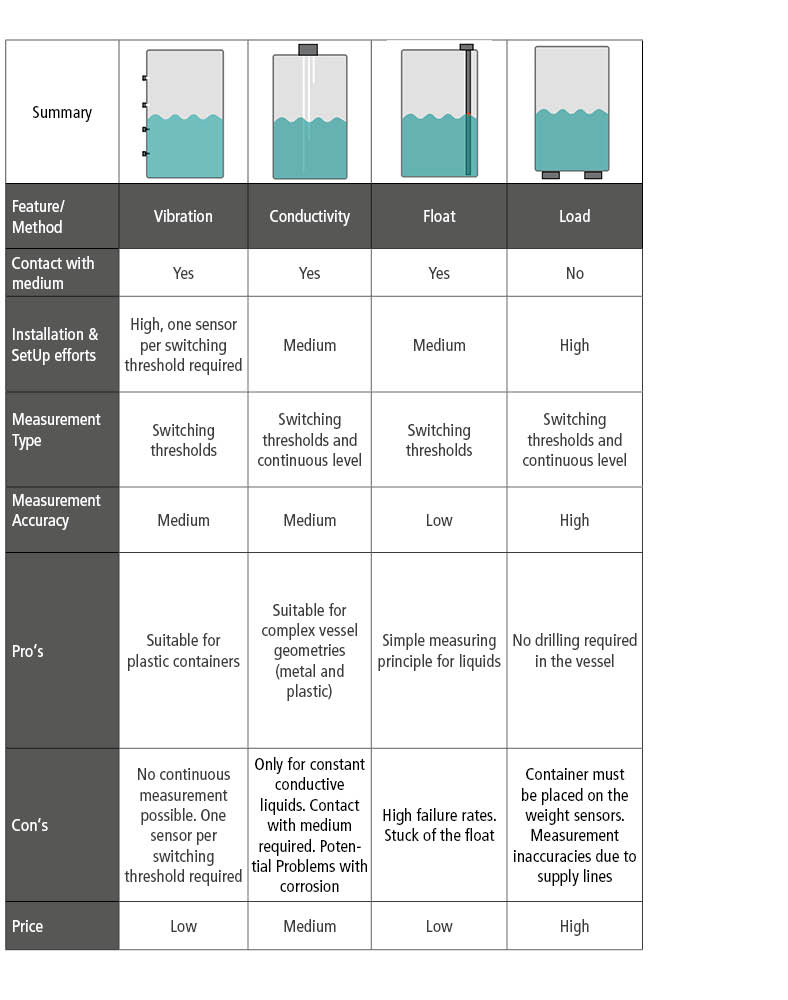

As a specialist in level measurement, CAPTRON uses capacitive as well as ToF laser technology for level measurement.

As the figure on the right shows, the operating principle of capacitive level measurement is based on the change in capacitance of a capacitor. In this example, the probe rod and the vessel wall form the two electrodes, while the medium acts as the dielectric. The change in level causes a change in capacitance. An empty vessel has a low capacitance, while a filled vessel has a high capacitance.

Selection Criteria for Capacitive Probes

The selection criteria depend on numerous factors – 1-rod probes are used for metal vessels, while double-rod probes or a 1-rod probe with a cladding tube are used for plastic vessels. The environmental conditions, such as temperatures above 100 °C, and the required protection class, e.g. IP67, determine whether an external amplifier is required or what type of instrument connection is needed.

Special designs according to customer specifications

In every industry, very different requirements are placed on products and materials. That is why CAPTRON offers a range of probe systems that can be combined and customized. Depending on the application and type of vessel, the company's systems can be used to configure probes that meet very specific customer requirements - right down to probe lengths that are accurate to the millimeter. Custom designs are an important consideration, especially for different vessel sizes. CAPTRON meets these requirements and offers probes or even dual probes in the desired length and with sensors that measure many different liquids and powders. Due to the material options, corrosion does not occur. Special designs are developed according to customer specifications, especially the rod length can be determined to the centimeter and delivered within two weeks. CAPTRON's level sensors are extremely reliable and very accurate. There are systems that have been in operation for over 20 years. CAPTRON also takes care of the precise calibration of probes with regard to the vessel geometry, the measured material (DK value) and other influencing factors, such as temperature or the movement of an agitator, among others. Compact probes with integrated electronics in the housing or probes with external amplifiers are available. The external amplifier is connected via a shielded, temperature-resistant Teflon cable to the rod probe. Due to the spatial separation of the rod probe and the amplifier, these probes are suitable for temperatures of up to 230 °C.

German

German English

English Chinese

Chinese Polish

Polish

![[Translate to Englisch:] CAPTRON Kompaktsonde](/fileadmin/user_upload/data/fce/subpage-stage/CAPTRON-Fluid-Sensors-Compact-Probes-subpage-stage.jpg)

![[Translate to Englisch:] symbol Time of Flight](/fileadmin/user_upload/ToF_Schuettgut_web.png)

![[Translate to Englisch:] symbol optische Reflektionsmessung](/fileadmin/user_upload/optisch_web.png)

![[Translate to Englisch:] symbol der kapazitive Füllstandsmessung](/fileadmin/user_upload/Kapazitiv_web.png)

![[Translate to Englisch:] Füllstandsmessung durch Ultraschall](/fileadmin/user_upload/Ultraschall_web.png)

![[Translate to Englisch:] Füllstandsmessung mittels Radar](/fileadmin/user_upload/Radar_web.png)

![[Translate to Englisch:] Füllstandsmessung mittels Vibrationssensoren](/fileadmin/user_upload/Vibration_web.png)

![[Translate to Englisch:] Füllstandsmessung durch Prüfung der Leitfähigkeit](/fileadmin/user_upload/Leitfaehigkeit_web.png)

![[Translate to Englisch:] Füllstandsmessung mittels Schwimmer](/fileadmin/user_upload/Schwimmer_web.png)

![[Translate to Englisch:] Füllstandsmessung mittels Last](/fileadmin/user_upload/Last_web.png)

![[Translate to Englisch:] CAPTRON kapazitive Füllstandsmessung](/fileadmin/user_upload/CAPTRON-blog-level-measurement-slider-03.jpg)