"Capacitive SENSORswitches offer many advantages for the car manufacturers as well as their operators, such as cities and municipalities," says Managing Director Philip Bellm. “we have learned a lot from more than 20 years of experience in transport. For decades, we have been designing sensors targeting the special requirements in transport – with success.”

The solution to reducing costs

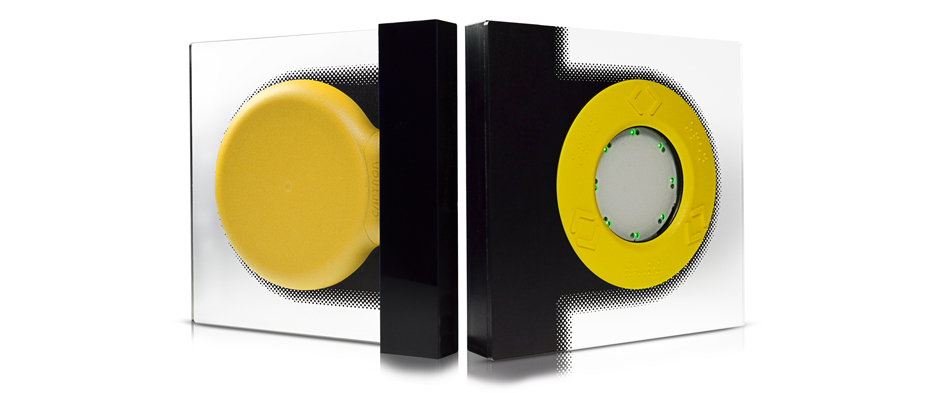

This solution can also contribute to the reduction of weight, noise, and vibrations in transport vehicle construction and prevent additional costs for maintenance and wear.

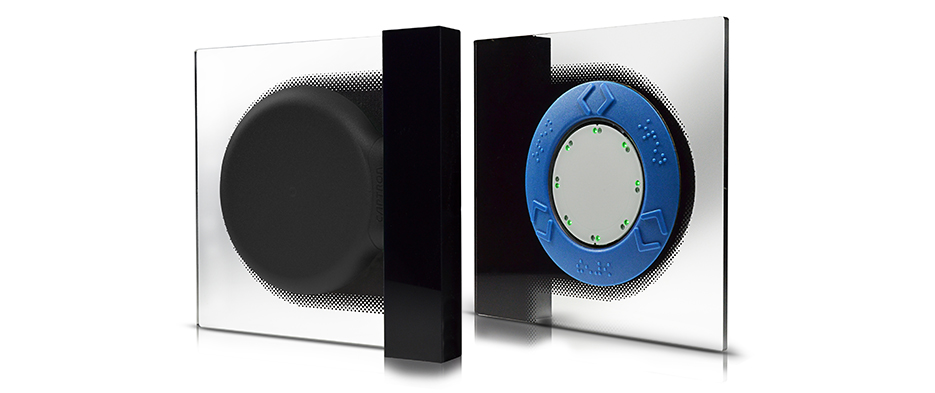

Mechanical fastening (screws, nuts, drilling/cutting of holes) as well as storage costs for assembly tools and materials are completely obsolete. Mechanical buttons and switches are also very susceptible to wear and tear due to their design with movable parts. Vehicle owners avoid these additional operating costs, since electronic buttons are completely wear-resistant and maintenance-free.

Quality and longevity guaranteed

The global players in traffic and transport have been relying on the decades of CAPTRON’s experience. Manufacturers of city buses and railway vehicles as well as door manufacturers, cities and municipalities – all have one good reason to choose products from CAPTRON: Impressive quality.

- Several 100 million switching cycles with SENSORswitches

- Maintenance-free and wear-resistant electronics

- Highly intelligent combination of technology and algorithm

- Consulting and project-related advancement of all products

Due to its impact-resistant and waterproof construction, CAPTRON's electronic door opening buttons are particularly resistant to extreme weather conditions such as heat, cold, rain, or dirt.

The buttons are also protected against vandalism in the form of impact on the touch surface or by flames from lighters, as the SENSORswitch production stress performance video demonstrates impressively.

+ SENSORswitch stress-test video part 2.0

German

German English

English

![[Translate to Englisch:] CAPTRON Stress Test Video Fritteuse](/fileadmin/user_upload/data/fce/videos/CAPTRON-Stress-Test-Video-Vol-2-Szene-Fritteuse.jpg)